The company’s business is based on manufacturing with its fleet of CNC systems – machinery that is continuously maintained to reflect the state of the art. Units housed in the company’s fully air-conditioned 2,000 m2 production building include CNC Milling Systems, CNC Turning Systems, Metrology and QA (Quality assurance), Conventional Manufacturing/Special Applications and Warehouse.

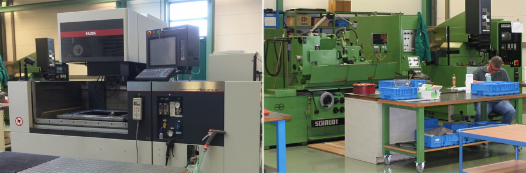

MillingThe largest unit is CNC Milling, which offers an impressive array of machinery including the very latest Hermle 5-axis machining centres, for example, with Heidenhain controls, magazines and automated pallet depots. |  |

TurningIn the other primary manufacturing unit, ultramodern Gildemeister 3-axis CNC lathes with Heidenhain controls ensure outstanding product quality. |  |

WarehouseThe large, company-internal warehouse ensures the high availability of the most commonly used materials and thus considerably reduces customers delivery times. |  |

Conventional machining and other manufacturing techniquesComplementing the traditional methods of turning, milling and drilling, Fischer CNC-Technik GmbH also offers a wide range of conventional techniques such as honing, welding, lapping and surface/cylindrical grinding. The portfolio is rounded off by other special applications, with examples including die sinking EDM and wire erosion. These can be used to machine any conducting material regardless of its hardness. The contours produced are sharp-edged, satisfying the most demanding requirements for dimensional stability and geometrical accuracy. |  |

Quality assurance (QA)The physical layout of our manufacturing facilities is both carefully and generously dimensioned, thus offering plenty of space for QA work between individual process steps. In addition, final inspections are handled by a dedicated Quality Assurance unit. Here, four Zeiss Prismo Calypso and Vista measuring machines with a large table for 12-cylinder engine blocks and button station deliver the content later depicted in the test reports sent with them to the customer. |  |